Izinto zokubumba eziqhelekileyo zesitofu zikhemikhali kwaye zihlulwe ngokwasemzimbeni zibe yi-acrylate, i-styrene kunye ne-styrene.I-monomer nganye ineempawu ezahlukeneyo: i-acrylate inamandla aphezulu, i-thermal kunye nokuzinza kweekhemikhali: ukusuka kwindawo yokujonga i-morphological, i-polymerization ye-monomers emithathu ivelisa i-copolymer yesigaba sesithathu, esahlulwe ngamanqanaba amabini: enye yinqanaba eliqhubekayo le-styrene propylene diene. , kunye nesinye isigaba esisasaziweyo serabha ye-polybutylene.

Ukusebenza kwe-ABS ikakhulu kuxhomekeke kumyinge wee-monomers ezintathu kunye nesakhiwo semolekyuli sezigaba ezibini.Oku kuvumela ukuguquguquka okukhulu kuyilo lwemveliso kwaye ivumela ukuveliswa kwamakhulu eenaliti ezisemgangathweni ezahlukeneyo kunye nezixhobo zokubumba kwimarike.Ezi naliti zokubumba kunye nezixhobo zokubumba ezinomgangatho ohlukeneyo zineempawu ezahlukeneyo, ezifana nokuchasana kwempembelelo ephezulu, amafutha aphantsi kunye nokugqiba okuphezulu, kunye neempawu zokuguquka kobushushu obuphezulu.Ukubumba inaliti ye-ABS, imathiriyeli yokubumba enobuchule obuphezulu, iimpawu zenkangeleko, ukunyathela okuphantsi, uzinzo olubalaseleyo lomda kunye namandla anempembelelo ephezulu.Iimitha zamanzi kunye nezinye izixhobo zorhwebo, imikhono yentambo, iikhamera zoomatshini, iindlela zokutyibilika kunye neebheringi.Iphaneli yemoto,Ikhabhathi yesixhobo, isigqubuthelo sevili, ibhokisi yesipili, ifriji, isomisi seenwele, umxubi, umatshini wokulungisa ukutya, umatshini wokucheba ingca, indawo yokufowunela, ibhodi yokuchwetheza, inqwelo yegalufa, njl.

Iimeko zenkqubo yesitofu sokungunda: kufuneka yomiswe phambi kokuba iqhutywe.Imeko yokumisa ekhuthazwayo yi-80 ~ 90 iiyure ubuncinane, kwaye ukushisa kwezinto kufuneka kube ngaphantsi kwe-0.1%.Ubushushu obunyibilikayo: 210 ~ 280c;Ubushushu obucetyiswayo: 245 ℃.Iqondo lobushushu lokungunda: 25 ~ 70C, iqondo lobushushu lokungunda liya kuchaphazela ukugqitywa komphezulu wamalungu eplastiki, ngelixa ubushushu obuphantsi buya kunciphisa ukugqitywa komphezulu.Uxinzelelo lokutofa: 500 ~ 1000bar.Isantya sokutofa: isantya esiphakathi.

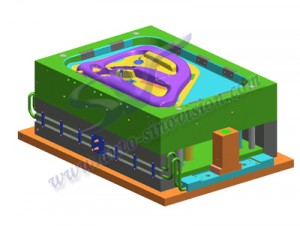

Iisitofu sokungundaizinto zokuyila iteknoloji yeplastiki ye-ABS idibanisa iimpawu zamacandelo amathathu aphambili.Phakathi kwabo, i-Acrylonite inobunzima obuphezulu, amandla aphezulu, ukumelana nokushisa kunye nokumelana nokubola;I-Butadiene inokumelana nempembelelo kunye nokuqina;I-styrene ine-luster ephezulu, kulula ukuyibala kunye nokusebenza;Olu hlalutyo lungentla lweempawu zamacandelo amathathu ahlukeneyo lenza ukuba izinto zokubumba inaliti ye-ABS zikhule zibe "ngumgangatho owomeleleyo" kunye "nokuqina" kwenkqubo ebanzi yokusebenza kwe-thermoplastics yokuqina okuphezulu.Lungisa umlinganiselo wezithako ezintathu ezisisiseko ze-ABS, kwaye ukusebenza kwayo kuya kutshintsha ngokufanelekileyo ukuhlangabezana neemfuno zezicelo ezahlukeneyo zedatha zamashishini, ezifana nokumelana okuphezulu kwe-ABS, i-ABS ekwazi ukumelana nobushushu, kunye ne-gloss high ABS.Uphando lwezixhobo zokuvelisa i-ABS ye-injection mold ine-processability efanelekileyo, enokuthi yenziwe ngokuphucula ukubunjwa kwe-injection, i-extrusion, i-hot molding kunye nezinye iindlela ngexesha elifanayo, okanye ngokuthe ngqo ngokusaha, ukubhola, ukufayila, ukugaya kunye nezinye iindlela.Inokuxutywa kunye ne-solvents ye-organic, kwaye inokulawula ngokufanelekileyo i-coating kunye nokulungiswa kolwazi lomhlaba (njenge-electroplating) kunye nonyango.Iplastiki ye-ABS ikwalukhetho olufanelekileyo kubantu abangakwaziyo ukuthatha indawo yomthi kunye nezixhobo zokwakha.Isitofu se-ABS sezinto ezinxulumene nokungunda zinamandla athile aphezulu, ubunzima obulula kunye nobunzima bomhlaba obuphezulu.Umsebenzi wayo wolawulo lwesicelo usakhula.Iiplastiki ze-ABS zisetyenziswa kakhulu kushishino lwaseTshayina.Umgangatho weemveliso zokubumba inaliti ye-ABS idla ngokusetyenziselwaiindawo ezivaliweyo zombane, iibhokisi, iinxalenye, iithoyi, njl.

Ixesha lokuposa: Oct-21-2022