Kwimeko yemigca yomoya okanye imigca yejethi kufuphi nendawo yokungena irabha yeiindawo ezibunjiweyo zesitofungexesha lemveliso, uhlalutyo olulandelayo lunokubhekiswa kulo ukuze kuthelekiswe nokuphucula.Phakathi kwabo, ukunciphisa isantya sokutofa yeyona ndlela iphambili kuthi yokuphucula ingxaki yemigca yokutofa kunye nemigca yomoya, kwaye okwesibini kukujonga ukuba ubungakanani bendawo yokufaka irabha yesitofu incinci okanye incinci kakhulu.Ukubhaka imathiriyeli efanelekileyo ekrwada linyathelo elisisiseko lokuqinisekisa imveliso, kwaye kufuneka yenziwe kakuhle.

Kukho iiyantlukwano kwinkangeleko yeglue inlet air lines kunye nejet line ezibangelwa zizizathu ezahlukeneyo.Nika ingqalelo ngakumbi ukuqwalaselwa ngamaxesha aqhelekileyo, anokukhawuleza ukuhlalutya kunye nesisombululo seengxaki.

Ukuba izinto ekrwada yePCukuveliswa kubhakiwe ngokupheleleyo, okanye kuya kubakho umoya okanye imigca yokudubula kwindawo yokungena kwamanzi, ezi zinto zilandelayo kufuneka ziqwalaselwe:

1. Inqanaba lokuqala lokutofa kweglue isantya sikhawuleza kakhulu.Esi sesona sizathu siphambili sophawu lomoya xa ungena emanzini.Ibangela i-eddy current enzulu xa incatho encamathelayo enyibilikayo ingena kumngxuma, ikhokelela kuphawu lomoya oyi-eddy.Ngoko ke, le yinto yokuqala ekufuneka i-shunter iqwalasele kwaye izame ukunciphisa isantya.

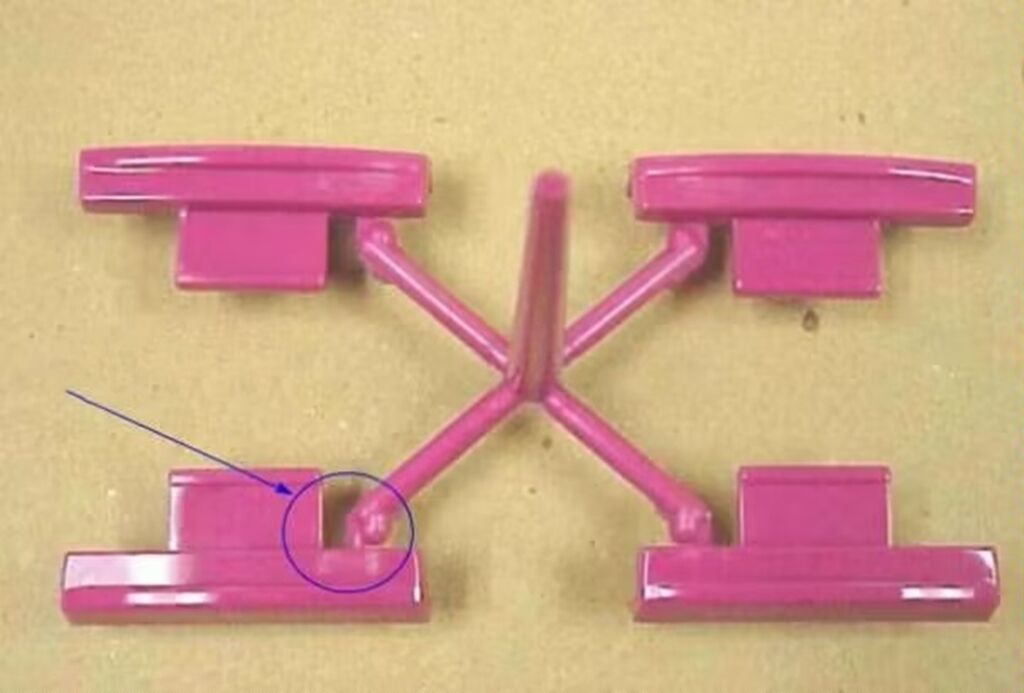

2. I-inlet ye-rubber incinci kakhulu okanye incinci kakhulu, nayo iyinto ebalulekileyo yokubangela umoya kunye namanqaku okudubula.Ngenxa yokuba i-glue inlet incinci kakhulu okanye incinci kakhulu, iya kukhokelela kwisantya sokutofa kweglue yeglue enyibilikayo engena kwi-mold cavity ikhawuleza kakhulu, okukhokelela kwimigca yejethi kunye nemigca yomoya, ekwangunobangela wemigca yenyoka.Ngoko ke, ukuba ingxaki ayikwazi ukupheliswa nokuba isantya sincitshiswe kwinqanaba eliphantsi, kuyimfuneko ukuqwalasela ukuba i-inlet yamanzi incinci okanye incinci kakhulu, engaphantsi kwe-0.5mm okanye encinci.

3. Ubuninzi bodonga lwendawo yokubumba yesitofu kwindawo yokungena irabha, kulula ukuvelisa imibimbi yomoya, engaphezulu kwe-4mm.Ngenxa yokuba ubukhulu bodonga bukhulu, kulula ukuvelisa i-eddy yangoku xa i-adhesive inyibilika ingena kwindawo yokungena kwamanzi, okukhokelela ekuveliseni i-air ripple.Kule meko, ngamanye amaxesha kunzima ukuphelisa i-air ripple ngokukhulisa i-inlet yamanzi kunye nokunciphisa isantya.Ngeli xesha, kungcono ukutshintsha i-rubber inlet kwindawo enodonga oluncinci, njengendawo engaphantsi kwe-3mm.

4. Ukukhanya ngakumbi komphezulu wengundoumgodi, oko kukuthi, ngokukhona umphezulu wenaliti yokubumba ukhanya ngakumbi, kulula ukuvelisa imibimbi yomoya.Ukuba indawo yokubumba inaliti iqaqambe kakhulu, iintambo zomoya ezincinci ziya kutyhilwa.

5. Ukuba ubushushu be-adhesive melt okanye i-mold iphantsi kakhulu, iindawo ezibunjiweyo ze-injection nazo ziya kuba nemigca ye-injection ebangelwa yi-gel, ehamba kunye nemigca yomoya ethule.

6. Kwizinto eziphathekayo ezilula ukutshisa, ukuba ukushisa kwe-melt kuphezulu kakhulu, i-air ripple ebangelwa yi-gas eninzi yokubola iya kwenzeka.

7. Umgangatho weglue kufuneka uqinisekiswe.Uxinzelelo lwangasemva lwezinto zePC kufuneka lubekwe kwi-10bar ~ 25bar.Isantya sokunyibilika kweglue kufuneka sibekwe kwisantya esiphakathi.Ukukhutshwa kweglue akufanele kube kude kakhulu.Ngaphandle koko, ukuba umoya uphonswa kwibhobho yompu, imveliso iya kuba nesitshizi.I-glue extraction stroke kufuneka ibekwe ngokuhambelana nomva.Uxinzelelo olukhulu ngasemva kukuba, ixesha elide i-glue extraction stroke iseti, ngokubanzi 2mm ~ 10mm.

8. Ubushushu bombhobho buphezulu kakhulu okanye buphantsi kakhulu.Ukuba iphezulu kakhulu, irabha kwi-nozzle iya kubola kwaye ivelise imigca yomoya;Iphantsi kakhulu, inaliti ayigudi, yenza imigca yejethi, okanye ushicilelo olubandayo lweoffset.

Ixesha lokuposa: Oct-25-2022